| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : Lanshuo

Model Number : LSW-300

Certification : CE

Place of Origin : China

MOQ : 1 set

Price : USD 1000-20000 / set

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 2000 sets per year

Delivery Time : 5-7 working days after receiving advanced payments

Packaging Details : wooden boxes

Type : Induction Heating Machine

Working Voltage : 380V, 50/60HZ

Max Input Current : 480A

Max Input Power : 300kw

Oscillation Frequency : 10-20KHZ

Duty Cycle : 100%

Cooling Water Flow : 70L/Min,0.2MPa

Weight : 540kg

Dimension : 1070*640*1870mm / 1020*530*690mm

Color : Optional

1. Brief introduction of IGBT induction heating machine:

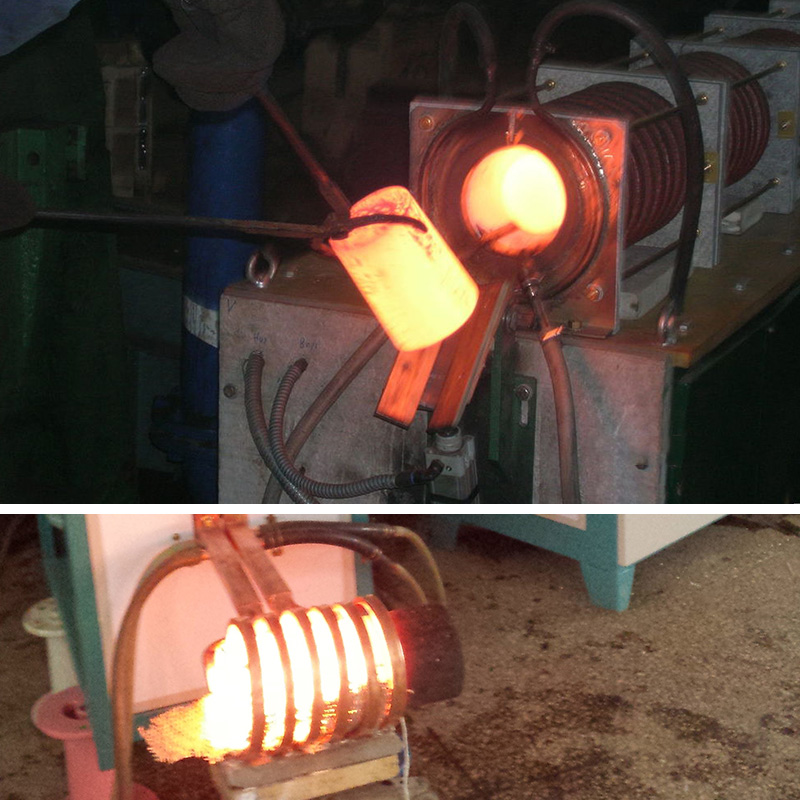

Our high frequency induction heating machine adopts IGBT series and parallel induction heating technology as the core. The induction heating machine heats the work piece to a certain temperature, and then cools it rapidly to change its machine structure to achieve some special mechanic properties.

2. Features of IGBT induction heating machine: suitable for heating steel bars, pipes, plates and angle steels.

1. Be applicable to heating, quenching / hardening, etc.

2. IGBT technology as the core.

3. Environmentally friendly: no air pollution, no dust and little noise.

4. Reduced operating cost: high automation, fewer operators needed.

5. Energy saving: high energy conversion.

6. High efficiency: Metal can be heated to its desired temperature, even its melting point, instantly.

7. Duty cycle 100%: can work for 24 hours without a stop.

3. Technical Parameters of LSW-300 IGBT induction heating machine:

| Model | LSW-300 |

| Working Voltage | 380V, 50/60HZ |

| Max input power | 300kw |

| Oscillation frequency | 10-20KHZ |

| Duty cycle | 100% |

| Cooling water flow | 70L/Min,0.2MPa |

| Weight | 540kg |

| Dimension (L*W*H ) | 1070*640*1870mm / 1020*530*690mm |

| Material | stainless steel |

| Color | support customized |

| Usage | metal heating,quenching etc |

4. Applications of IGBT induction heating machine:

1. Heating: mainly for carbon steel, stainless steel, alloy, brass, aluminum etc heating.

2. Forging: whole and partial induction forging for metal bar.

3. Work piece hot forging and rolling: standard parts, fasteners, automobile parts, small hardware, round bar and billet, etc.

4. Specific application for the induction forging heater:

(1) bolts and nuts forging and hot upsetting

(2) pipe induction forging and forming

(3) auto parts (connecting rod, crank shaft, etc.), cast iron beam heating and continuous heating

(4) oxygen bottle forging

(5) rivet heating

(6) long / round / square / angle bar and billet heating, etc.

5. Main Features of IGBT induction heating machine:

1. High heating speed: more than 10 times higher than gas furnace's heating speed;

2. Less metal loss: the heating time is short, burning a small, compared to other heating methods, significantly reducing the amount of metal loss;

3. Little room occupying: small furnaces, the volume can be reduced to the extent of only three to five loading ingots, extrusion machines to meet production needs;

4. Environmentally friendly: no environmental pollution, good quality metal billets heated;

5. Mechanization and automation: good working conditions, can reduce the amount of operators;

6. Well-controlled temperature: metal billet heating process, the spindle temperature control can be achieved;

7. Low failure rate: can be configured side by side two induction furnaces (exchange use), to avoid shutdown, improve production efficiency.

6. LSW-300 IGBT IGBT induction heating machine:

As for packaging of induction heating machine: The machine is always packed with wrapping film for waterproof, and then put into a standard exporting plywood case with foam around for shockproof.

As for shipping of induction heating machine:

1. If you have a shipper in China, we can send the machines to him or her for free.

2. If you want us to send the machines to you directly, we can send them to any main port of China promptly.

7. Company Brief Introduction :

8. Customer Center:

9. Canton Fair

10. Related Products:

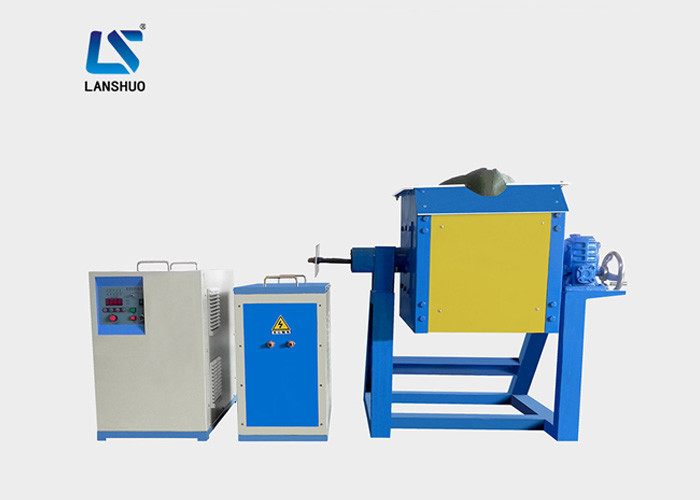

| KGPS Melting Furnace | LSZ Melting Furnace | Cooling Tower |

|  |  |

|

|

300kw Metal Induction Heating Unit , Induction Heating Furnace For Forging Images |